StratEdge Assembly Services

StratEdge Assembly Services, started in 1999, packages a wide variety of compound semiconductors and silicon in our new ISO 9001:2015 facility in Santee, California (near San Diego). We have a Class 1000 cleanroom, including Class 100 work areas with ESD control for performing sensitive operations, which is fully equipped with the most modern assembly equipment. StratEdge can customize packages and assembly services for your specific requirements.

StratEdge Assembly Services, started in 1999, packages a wide variety of compound semiconductors and silicon in our new ISO 9001:2015 facility in Santee, California (near San Diego). We have a Class 1000 cleanroom, including Class 100 work areas with ESD control for performing sensitive operations, which is fully equipped with the most modern assembly equipment. StratEdge can customize packages and assembly services for your specific requirements.

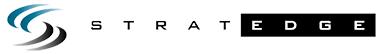

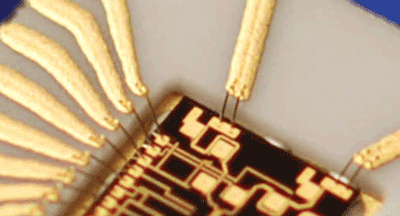

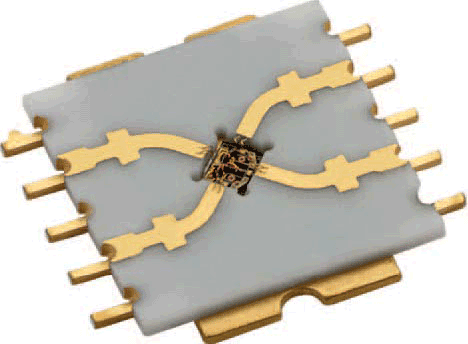

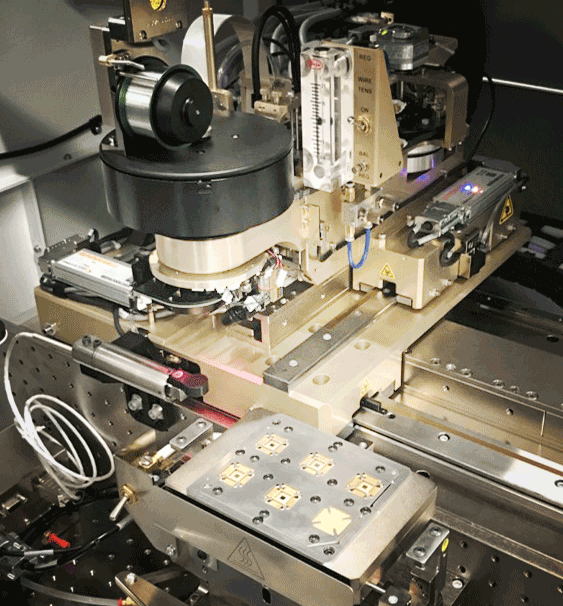

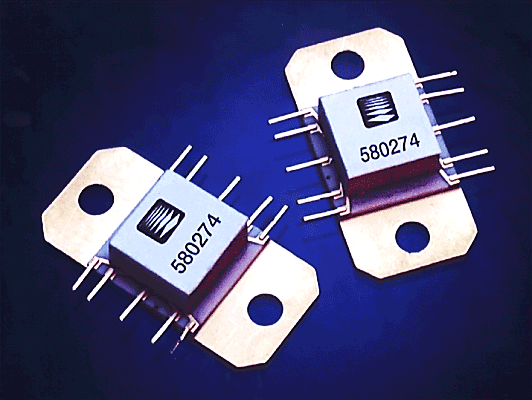

StratEdge specializes in the manufacture and assembly of high frequency and high speed MMIC devices, along with passive components including single- and multi-chip with 50-ohm lines. Our automated equipment can perform precise eutectic, epoxy die attachment, and wire bonding to ensure consistent loop lengths and heights for the best electrical performance. We assemble packages and lids manufactured by StratEdge as well as customer furnished packages and boards. The flexibility of the equipment and skill of our operators enables StratEdge to accommodate the numerous needs of our customers.

Assembly services also include high-speed fine wire wedge and ribbon bonding for deep access bonding. We can handle both orthogonal bonding and chain bonding. A large work area (305mm x 152mm / 12 in. x 6 in.) allows us to work with large boards and substrates.

Our component placement die attach system is the fastest and most reliable multiple die-type bonder on the market. The machine's 5µm placement accuracy capability, 250 millisecond tool change time, and excellent tool-to-tool planarity enables StratEdge to offer high-accuracy and peak performance across a large work area (914mm x 508mm / 36 in. x 20 in.).

The bonder is specially equipped for eutectic AuSn attachment of devices, achieving bond line thickness less than 6µm. We have perfected our proprietary eutectic die attach technology to get the best possible power output for gallium nitride (GaN) devices, and one that will result in lower junction temperatures and increased device reliability.

We specialize in:

RF and microwave devices, including gallium nitride (GaN) and gallium arsenide (GaAs)

RF and microwave devices, including gallium nitride (GaN) and gallium arsenide (GaAs)- High-frequency passive and active components

- MCM power connections

- Large complex hybrids

- Power amplifiers, low noise amplifiers, mixed signal devices

- MEMS

And our capabilities include:

Epoxy and eutectic die attach

Epoxy and eutectic die attach- Automated gold-tin (AuSn) die attach developed for GaN and GaAs devices

- Automatic and manual wedge wire bonding

- Ribbon bonding

- Low profile wire bonds

- Running stitch interconnects (die-to-die)

- 50-ohm lines for reducing wire lengths

- AuSn solder preform, low-temperature glass, and epoxy lid sealing

- Marking, lead forming, and tape-and-reel

- MIL-STD environmental testing

Lidding

StratEdge provides a variety of lids and services for attachment including:

Lids with B-stage epoxy. These are LCP or ceramic lids that are flat or cup-shaped sealed by a NASA-approved, low out-gassing epoxy. They pass fine and gross leak testing.

Lids with B-stage epoxy. These are LCP or ceramic lids that are flat or cup-shaped sealed by a NASA-approved, low out-gassing epoxy. They pass fine and gross leak testing. - Combo lids that are metal with gold-tin (AuSn) preforms.

After assembly, the packages are lidded and the leads are trimmed and formed. Post assembly services include labeling, bulk packaging, and preparation for delivery. StratEdge can accommodate special requests, such as grouping completed parts based on very tight electrical performance specifications, so they can be used together in specific applications.